Nitronic AG

Nitronic AG

Coaxial cable stripping machines and fine wire stripping equipment

Nitronic

Nitronic is a leading global niche-market supplier of high precision wire and cable stripping machines and innovative compact hardness testers. Nitronic sees itself as a partner to its customers, working with them through every stage of their products life cycle – from product launch and growth, through maturity and all the way to product phase out. Our customers benefit from over 30 years’ experience in developing and manufacturing wire processing solutions. Nitronic is known for reliable, high performance stripping machines and tools, which meet the highest standards of precision and cost efficiency. Nitronic's customers are typically global operated companies that hold leading positions in their respective industries. Our solutions enable them to optimize their production processes, thereby strengthening their leadership. These customers operate, amongst others, in the Electronic, Telecommunication, Medical, Aerospace, Military and Automotive industries. Nitronic's operations are divided into two divisions: cable processing and hardness testing. All our products are developed and manufactured in-house in Switzerland.

History

Nitronic was founded in the Swiss town of Nidau in 1977. For the first 10 years, Nitronic had developed and manufactured electronic instruments for nuclear research and the medicinal industry. Nitronic entered into the cable processing industry in 1984 with the cooperation of Stepan Engineering.. This resulted in the worlds first coaxial cable stripping machine CO207. Further models followed and set a new standard in cable processing.

- Coaxial cables: CO207, CO257, CO8015, HC207, MP257, MP8015

- Microcoaxial cables: MC252

- Semi-rigid cables: SR1000

- Fibre optic cables FO7045, FS7030, FS7035

These products were distributed exclusively by Schleuniger Switzerland.

In 2005 Nitronic released its high precision stripping tool the MiniStrip, which was the first to be distributed by Nitronic’s own distribution network. It was followed by the ST215 and ST215W wire stripping machines as well as the redesigned ST730 & ST730T coaxial cable stripping machines. Today Nitronic has a worldwide sales- and service network.

An important addition to the business was made in 2004, with the launch of the portable hardness tester HRC3070. The innovative construction and measuring principle allowed Nitronic to build a tester in the shape of a pen at a reasonable price. This is the most compact hardness tester on the market!

In 2008, Nitronic was converted to a non-stock corporation Nitronic AG. Furthermore, Nitronic moved to its new location at the Mattenstrasse.

If you have any questions, please don’t hesitate to contact us.

Products

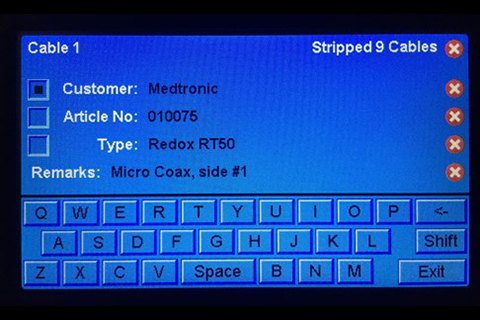

New Coaxial Cable Stripping Machine ST730T with Micro-Coax mode

DOWNLOAD ST730T PDF (115 KB) (115 KB)

Description:

The ST730T not only meets, but exceeds many requirements for a truly flexible wire processing machine. Not only is the stripping of coaxial cable or triaxial cable a breeze, but now the ability to switch over to Micro-coax mode is a first! This is the only machine on the market that allows you to process such a wide range of coaxial cables. Some down to as small as 36awg.

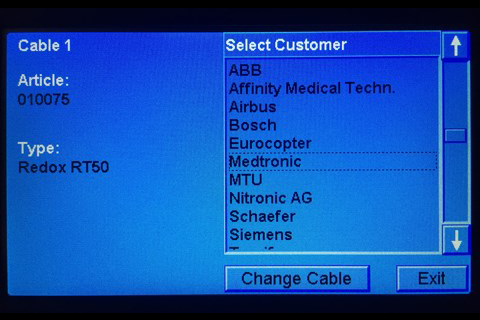

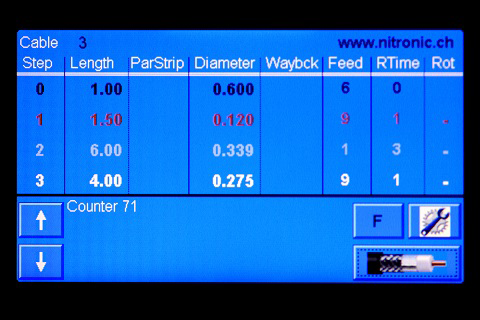

Set up times are eliminated because when selecting stored cable parameters, the machine sets itself up! The job is further simplified through the built in counter and the ability of setting program sequences. The safe and easy operation via the key pad or colorful touch screen allows for quick and reliable machine settings when changing to a different cable program. Stripping parameters can be protected by selecting a password, this can be accessed through authorized personnel.

Options available are: WinCoax PC Software for data storage and archiving. This software is compatible with both the Nitronic ST730T and Schleuniger MP machines. Also, a Foot pedal option is available

The stripping machine ST730T definitely impresses, due to its high precision, quality workmanship, longevity and it guarantees the highest flexibility with repeatable productivity!

The user friendly programming via the colorful touch screen allows for quick and easy machine set up or changing to different cable programs. Jobs are further simplified with the enhanced search engine which allows you to quickly find saved programs by Customer, Article number, Cable type, Remarks or Program numbers. Set up times are eliminated when selecting these stored programs because the machine actually sets itself up!

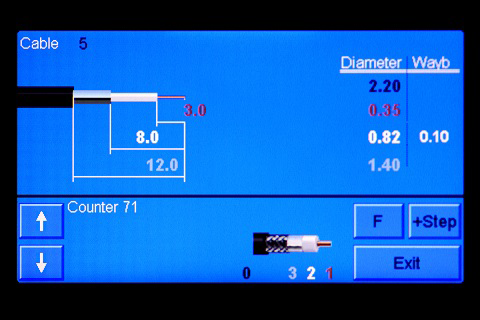

All Stripping parameters are easily accessed in the standard screen or in the beautiful graphics screen. The cable is illustrated exactly as programmed and can be protected by selecting a password, these can be accessed through authorized personnel.

The stripping machine ST730T definitely impresses, With the most flexible, high precision coaxial cable stripping machine on the market. Nitronic is built with quality workmanship and guarantees repeatable productivity and longevity.

Range of Applications

Coaxial cable processing, Triaxial cable processing, for all industries including the aviation and aerospace industries.

Examples Of Use

Stripping of coaxial cable in up to 9 steps, with or without semi strip including way-back function.

Features

- Outer cable diameter max 7 mm (0.28’’)

- Stripping length up to 30 mm (1.18’’)

- 99 program storage

- Adjustable diameter feed rate

- Adaptive clamping force

- Wayback or partial strip

- Sensor activated start cycle

- Foot pedal activated start cycle (optional)

- Left or right rotation/twisting

- Suitable for Teflon and Kapton and other hard to strip insulations

- RS232 interface

- 100, 115 and 230VAC power supply

Options

- WinCoax Software for Data backup and for visualization

- Foot pedal

- Made in Switzerland

ST215 / ST215W – Stripping and Twisting machine

ST215/ST215W PDF (159 KB)

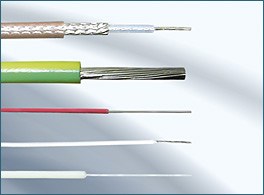

The cable Stripping and Twisting machine ST215 and ST215W (with wayback) was specially developed for small wires and cables. It features an innovative four-blade system, which provides very accurate and exact repeatable stripping results.

The coating is removed by cutting with rotating blades and strip-off in one single step. This innovative procedure allows processing of

- Coax/Microcoax cables

- Teflon or Kapton coated cables

- Sucoform SM86 cables from Huber & Suhner

Furthermore, wires are twisted during the stripping process. The high precision avoids damage to wires or dielectric. In addition, a centering unit allows very high precision stripping for high-end applications. The centering unit is infinitely adjustable and assures that the cable is centered respectively to the cutting blades. User influences regarding the stripping quality are eliminated.

Precision blade diameter control with a micrometer scale, allows a quick set-up of diameter. The locking screw of the diameter adjusting system makes the machine available even for military and aerospace applications. The quick length control is equipped with a sensor which initiates the stripping process. The high quality of the product guaranties a precise repetitiveness.

The all new ST215W features two additional functions.

– The rotation of the stripping head can be stopped prior to pull-off. This allows to twist or not the strands.

– The second new function is the adjustable Wayback. This function will open the blades a little prior to pull-off. This increases the stripping quality, especially when the wires have important diameter tolerances.

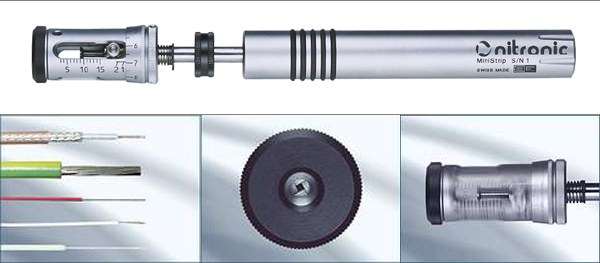

Nitronic MiniStrip –Cable Stripping Tool

The cable stripping tool Nitronic MiniStrip was specially developed for thin wires and cables. It features a four-blade system, which provides exact repeatable results for stripping wires and cables.

The coating is removed by rotating blades and stripped-off in one single step, depending on stripping length and cable, the wires are also twisted. This innovative design allows for processing fiber optic cables as well as coaxial cables and Teflon coated cables. The high precision design prevents damage to wires or fibers.

Precision blade diameter is controlled with a micrometer, which allows for a quick set-up of diameters. The locking screw of the diameter adjusting system makes the tool available even for military applications (mil-spec). The high quality construction of the ministrip guarantees a precise repetitiveness.

Features

- Wire size ranges from 0.16 mm (0.006”) to 1.5 mm (0.06”) (18 – 38 AWG), depending on insulation-type, down to 0.10 mm (0.004″) 38 AWG

- Outer cable diameter max. 2.5 mm (0.1’’)

- Stripping length up to 15 mm (0.6’’)

- Four cutting blades on one single plane

- Rotating cut

- No wire damage

- Fast and easy change of length and diameter settings

- Mobile, no power supply

- HSS blades can be replaced by user without tools

- Suitable for Teflon, PVC, Kynar and Kapton insulations

- Attractive price

Centering unit

The new centering unit allows for very high precision stripping especially for high-end applications. It is available as an option for the Nitronic MiniStrip. The centering unit is infinitely adjustable and makes sure that the cable is perfectly centered to the cutting blades. This involves the following advantages:

- The user cannot influence the stripping quality

- The stripping diameter can be adjusted very close to the conductor, dielectric or shield. In this way very thin insulations can be stripped.

- Wire damage is prevented

Bench Clamp

For production use we developed an aluminum bench clamp for the Nitronic MiniStrip. This elegant accessory is equipped with a special plastic, which will not damage the MiniStrip

Made in Switzerland

The MiniStrip is developed and manufactured in Switzerland by Nitronic AG. For more than 20 years, Nitronic has developed electronic / micro-electronic controls and mechanical solutions for cable processing.